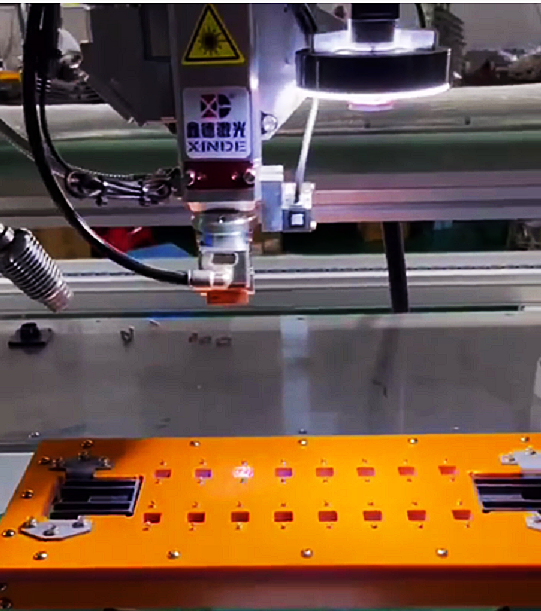

Laser welding uses high energy laser pulses to locally heat a material in a small area. The energy of the laser radiation is transmitted through heat into the material, causing it to melt and form a specific molten pool. It is a new type of welding method, mainly used for welding thin-wall material precision parts, spot welding butt welding overlap sealing welding, etc., small weld width, small heat affected zone deformation, fast welding speed, smooth weld, high welding quality, precision can be accurately controlled, high positioning accuracy, and easy automation. Laser welding machine is often called laser welding machine energy negative feedback laser welding machine laser cold welding machine laser argon welding machine laser welding equipment. With the continuous development of science and technology, the traditional welding method in many industrial technology can not meet the special requirements of materials, laser welding machine has the advantages of low bonding strength, wide heat affected zone, especially in many industries has gradually replaced the traditional welding method.

Three defects of laser welding

Laser technology has been paid special attention in aluminum alloy welding field because of its characteristics of low welding heat input, small influence on welding hot zone and not easy deformation. But on the other hand, because of its own existing defects, there are three welding difficulties in laser welding. So how do you do it subtly?

Welding difficulties, low laser absorption of the material

a) Adopt appropriate surface pretreatment process. For example, sandpaper grinding, surface chemical etching, surface plating and other pretreatment measures. Increase the absorption rate of the material to the laser.

b) Reduce spot size and increase laser power density.

c) Change the welding structure so that the laser beam can form multiple reflections in the gap. Easy to weld aluminum alloy

Welding difficulty two, easy to produce air hole and thermal crack

1) After many welding tests and studies, it is found that adjusting the laser power waveform in the welding process can reduce the unstable collapse of pores, changing the Angle of laser beam irradiation and applying the magnetic field in welding can reduce the porosity generated during welding.

2) When using the YAG laser, the heat input can be controlled by adjusting the pulse waveform to reduce the crystallization crack.

Third, in the process of welding, the mechanical properties of welded joints decline

The mechanical properties of welded joints are caused by the instability of pores in aluminum alloy welding. Aluminum alloy mainly includes Zn, Mg, Lv three elements. In the welding. The boiling point of aluminum is higher than that of the other two elements. Therefore, when welding aluminum alloy elements, some low boiling point alloy elements can be added, which is conducive to the formation of small holes and the solidity of welding.

The high efficiency of laser welding of aluminum alloy makes people look forward to its development prospect. Therefore, some researchers have continuously developed new technologies such as laser-arc matching process and dual-focus technology to improve the stability of the welding process and the quality of the weld. Laser welding welding thickness and laser welding equipment power size, as well as equipment welding material is different, general laser welding function welding depth can reach 7mm, firmness can be achieved according to your needs.

The industry application of laser welding machine is as follows: bathroom industry: water pipe joint, tee, valve, shower welding. Glasses industry: stainless steel, titanium alloy and other materials buckle, precision welding frame and other positions. Hardware industry: impeller, kettle, handle and other complex stamping parts, casting welding. Automobile industry: engine cylinder head gasket, hydraulic tappet sealing welding, spark plug welding, filter welding and other medical industry: stainless steel seals, medical appliances, medical instruments, structural parts welding. Electronics industry: solid state relay sealing welding, connector connector welding, MP3 and other metal shell and structural parts. Motor shell and wire welding, optical fiber connectors connectors and other household hardware: kitchenware, stainless steel door handles, electronic components, sensors, watches, precision machinery, communications, crafts and other industries, automotive hydraulic tappets and other high-strength products welding products.

-

Inquire

- Mobile

- Mobile177-2247-7738

- WeChat

- Tiktok

- Video

- Top