As we all know, the concept of new energy vehicles has repeatedly swept the capital market, attracting consumers' extensive attention to batteries and energy storage. With the launch of concepts such as "carbon peak, carbon neutrality" and "clear water and lush mountains are gold and silver mountains", lithium battery, the core component of new energy vehicles, has been welcomed around the world. Lithium batteries are popular around the world because of their long life, fast charging, light weight and high energy density. Based on these advantages, lithium batteries are gradually replacing traditional batteries such as lead-acid.

According to the "New Energy Vehicle Industry Development Plan (2021-2035)" issued by The General Office of the State Council on November 2, 2020, it is estimated that the sales volume of new energy vehicles in China will reach about 20% of the total sales volume of new vehicles in 2025. Judging from the current data, there is a large growth space for lithium batteries in the future.

As a new type of clean energy, lithium battery can provide power for many types of vehicles, such as new energy vehicles, electric trains, golf carts and other different types. There are more than a dozen steps in the production of a lithium battery, and today we will focus on the laser welding process.

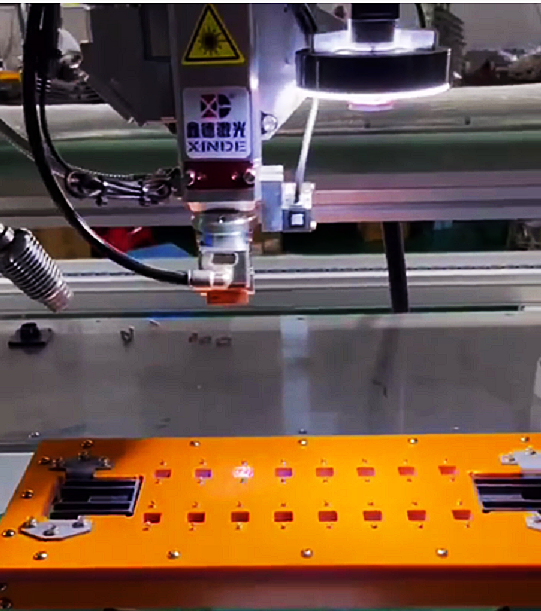

The role of laser welding machine is to provide customers with a complete set of lithium battery production equipment to ensure battery life and safety can be barrier-free operation. Compared with traditional welding methods such as argon arc welding and resistance welding, laser welding has obvious advantages. Laser welding energy concentration, high welding efficiency, high machining accuracy and fast speed, weld depth to width ratio is large. Because the heat input of laser beam in laser welding is small, the heat affected zone is small, the residual stress and deformation of the workpiece are small, and the welding is accurate. Because the power battery cell adhering to the principle of "light", so its welding material is generally thin aluminum alloy, its shell and cover are generally under 1.0mm. The typical battery manufacturer's base material is around 0.8mm thick, and laser welding plays an important role in keeping the sheets together.

There is no denying that manufacturers' demand for laser welding machines is also increasing due to the growing demand for new energy vehicles and lithium batteries.

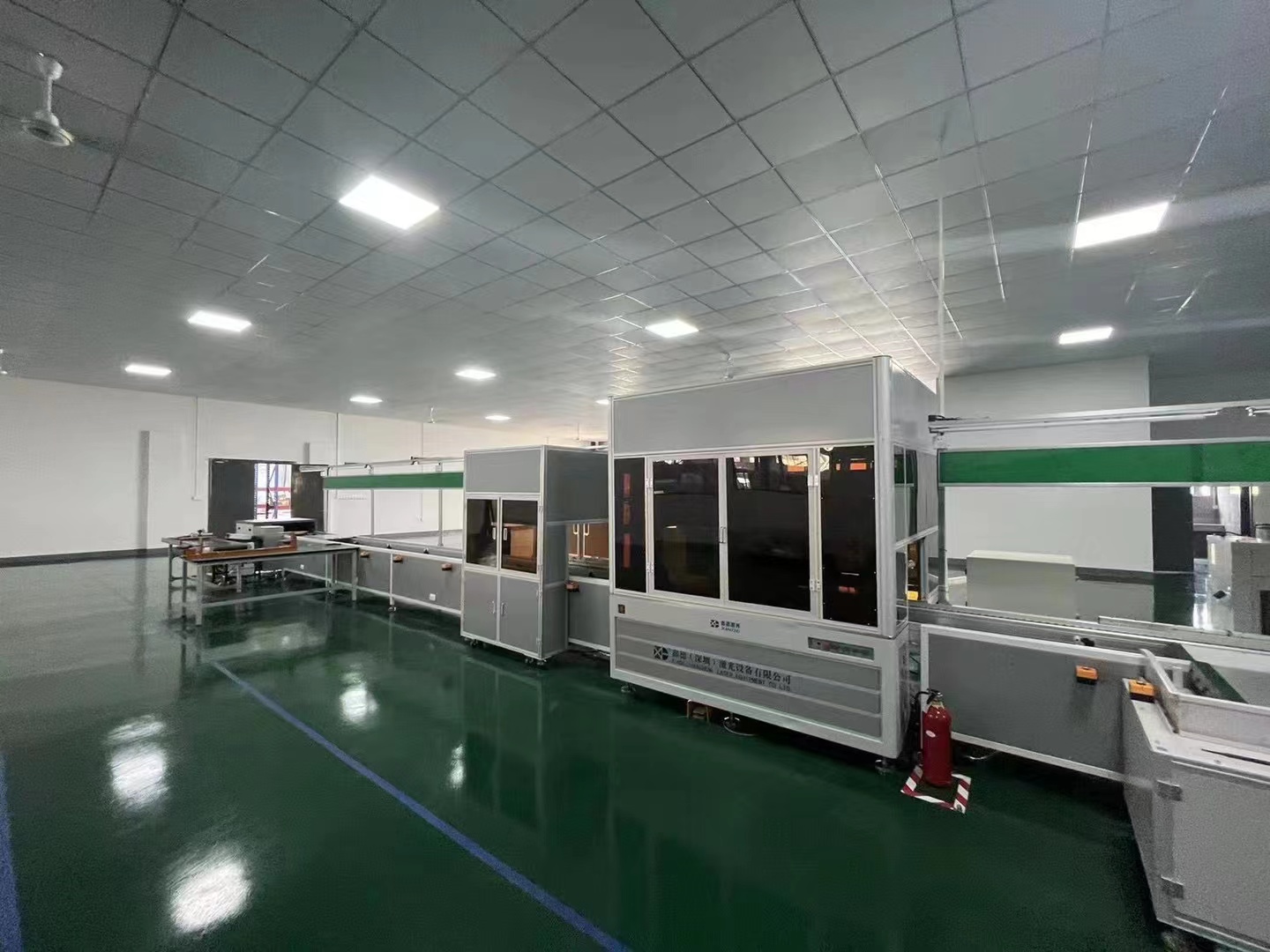

Xinde laser welding equipment is mainly used in the welding of new energy lithium battery pack: lithium battery to nickel, explosion-proof valve welding, battery pole nog welding, power battery shell and cover plate sealing welding, large monomer square shell lithium battery and large polymer power battery module pack welding, etc., for the majority of new energy lithium battery welding enterprises, to provide better automatic welding of a complete set of solutions.

-

Inquire

- Mobile

- Mobile177-2247-7738

- WeChat

- Tiktok

- Video

- Top