Welding is a very important manufacturing process from the manufacturing of lithium-ion battery cells to battery PACK. The conductivity, strength, air tightness, metal fatigue and corrosion resistance of lithium-ion batteries are typical battery welding quality evaluation standards. The selection of welding method and welding process will directly affect the cost, quality, safety and consistency of lithium-ion battery.

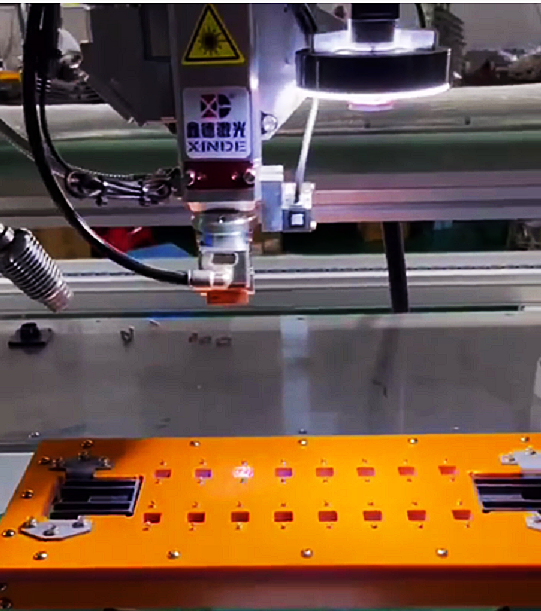

Among many welding methods, laser welding for lithium-ion battery processing stands out with the following advantages: first of all, laser welding has high energy density, small welding deformation, small heat affected zone, can effectively improve the precision of the workpiece, smooth weld without impurities, uniform and dense, no additional grinding work; Secondly, laser welding can be accurately controlled, focusing spot is small, high-precision positioning, with mechanical arm easy to realize automation, improve welding efficiency, reduce working hours, reduce costs; In addition, laser welding of thin sheet or thin wire is not as prone to weld as arc welding.

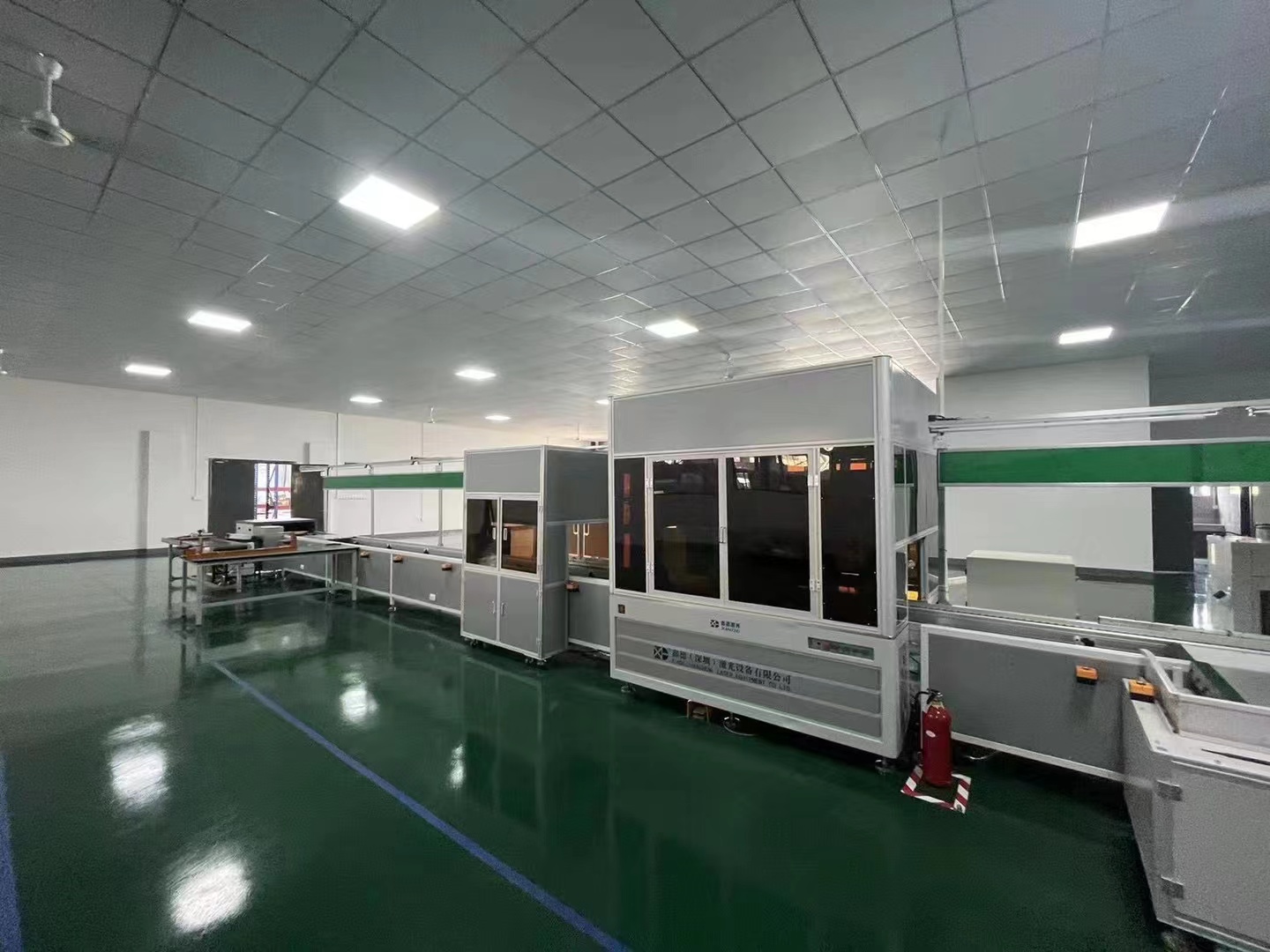

The technological advantage of laser welding lies in the wide variety of materials that can be welded and the welding between different materials can be realized. In the process of power lithium-ion battery welding, welding technology technicians will choose the appropriate laser and welding process parameters according to the battery material, shape, thickness, tension requirements, including welding speed, waveform, peak value, welding head tilt Angle, etc., to set reasonable welding process parameters, so as to ensure that the final welding effect meets the requirements of power lithium battery manufacturers.

-

Inquire

- Mobile

- Mobile177-2247-7738

- WeChat

- Tiktok

- Video

- Top