The new energy automobile industry is undoubtedly the industry with the most potential for development. In today's global automobile market, new energy vehicles have become the absolute mainstream and play an important role in it.

According to the data of China Association of Automobile Manufacturers, the production and sales volume of new energy vehicles in August reached 321,000 units, with a year-on-year growth of 193%. The cumulative sales volume from January to August reached 1,785,500 units, with a year-on-year growth of 209.7%, setting a new record.

At the same time, the power battery industry, which is closely related to automobiles, has also become one of the hot industries in the world.

To know, since this year, the battery upstream raw material demand has been explosive growth.

With the massive expansion of power battery capacity, the value of lithium devices themselves is also increasing, especially laser lithium devices.

Laser processing technology is the innovation of traditional processing, compared with the traditional processing technology, laser processing technology has the following characteristics:

1. Fast processing speed;

2. Small heat deformation and heat affected zone (suitable for processing high melting point, high hardness, special materials)

3. Local heat treatment of parts;

4. It can process complex shaped parts and small parts, and can also be processed in vacuum;

5. Processing without noise, no pollution to the environment;

6. Combined with computer technology, easy to realize automation;

7. Due to advanced processing methods, existing product structure and materials can be improved;

8. Can improve the quality of the workpiece;

In a word, the new round of power battery production expansion releases a huge amount of lithium equipment procurement demand, lithium production equipment manufacturers orders increased significantly.

With the rapid growth of the market demand of Chinese lithium battery industry and the large-scale expansion of the production capacity of lithium battery industry enterprises, a batch of domestic manufacturers of specialized laser welding equipment for lithium battery with better research and manufacturing ability have emerged.

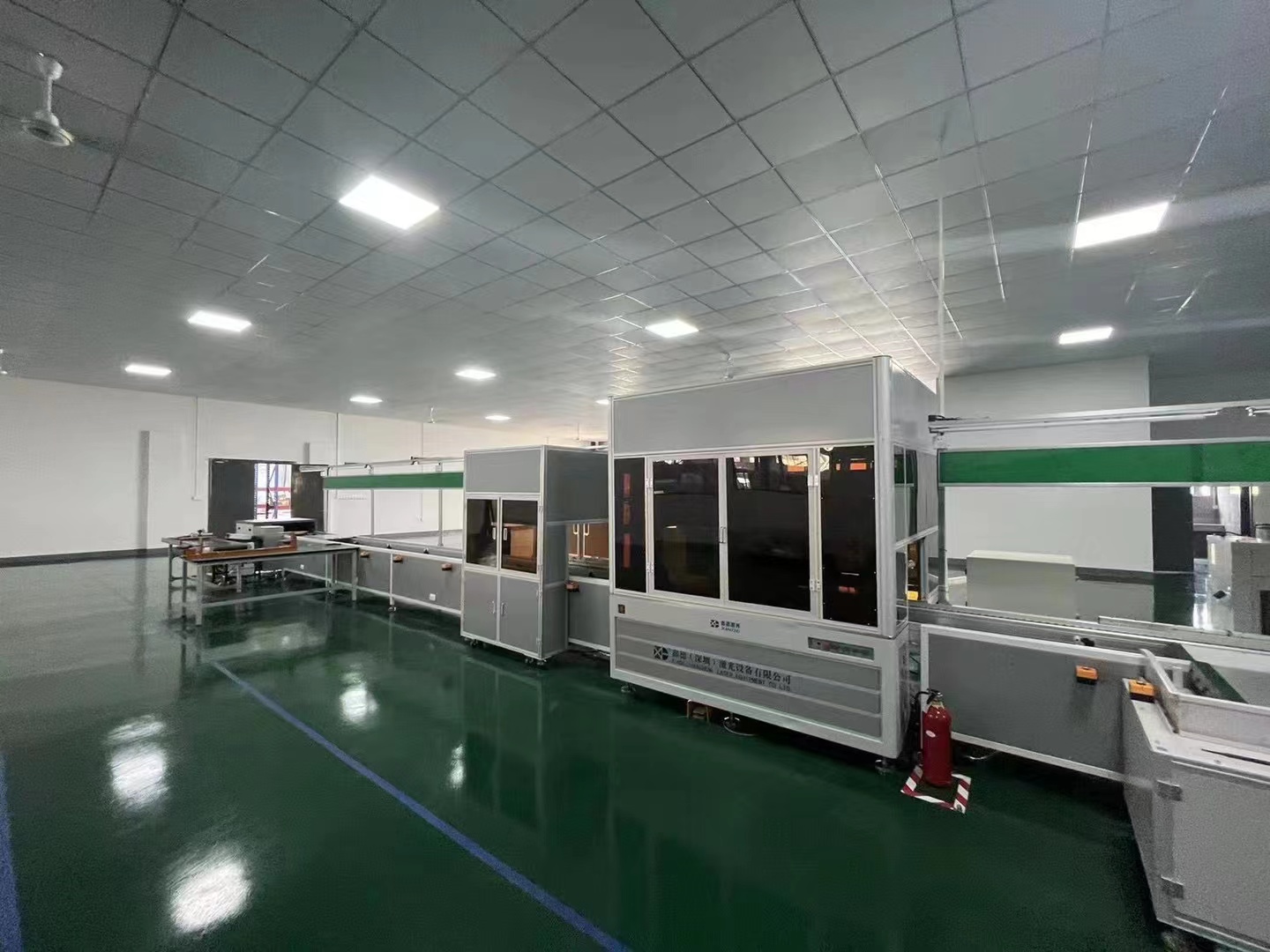

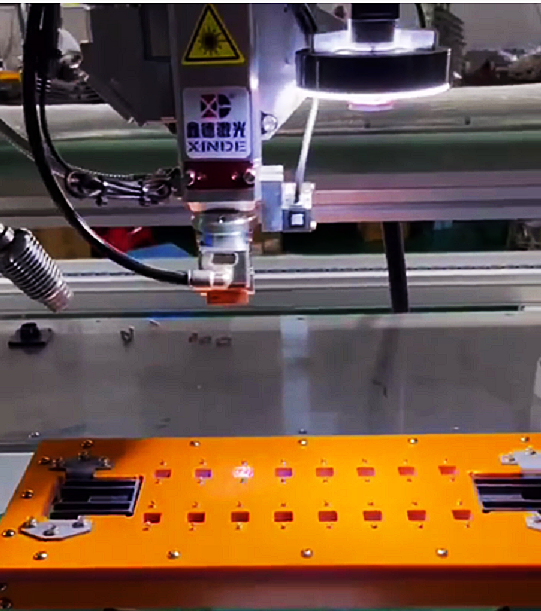

Xinde (Shenzhen) Laser Equipment is an excellent new enterprise focusing on new energy lithium battery equipment. Its laser welding equipment is mainly used in the welding of new energy lithium battery PACK, power battery module pack welding, etc. Xinde Laser has always been adhering to the "quality first, reputation first" purpose, with scientific management and high-end technical force, continue to deepen technical reform, innovation, dare to walk in the forefront of laser welding technology of lithium battery industry!

The promotion of new energy vehicles has increased the demand for battery manufacturers, and the capacity gap of power batteries has widened, which has become the home field of lithium battery manufacturers and lithium equipment manufacturers.

-

Inquire

- Mobile

- Mobile177-2247-7738

- WeChat

- Tiktok

- Video

- Top