1. Different uses of laser welding machine configuration is not the same, such as welding mold welding, welding jewelry jewelry welding, and automatic welding machine inside the galvanometer welding, optical fiber transmission laser welding machine, etc., the configuration of equipment is not the same, the price is naturally different.

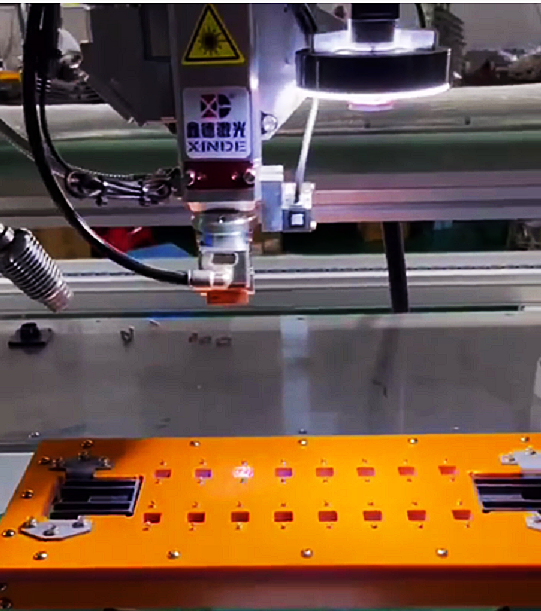

2. In addition, the automatic welding machine is generally more expensive than the manual welding machine, because the automatic need control system, CCD camera monitoring system and other supporting automatic configuration.

3. Some customers have customized requirements, so the price will be higher. For example, some production processes require the customization of some automatic fixtures, or the modification of the workbench, or the need to add other additional functional accessories.

4. The brand of accessories will also affect the quotation. Imported ones are usually more expensive than domestic ones, and domestic prices vary widely. It can be said that the price of parts can vary a lot.

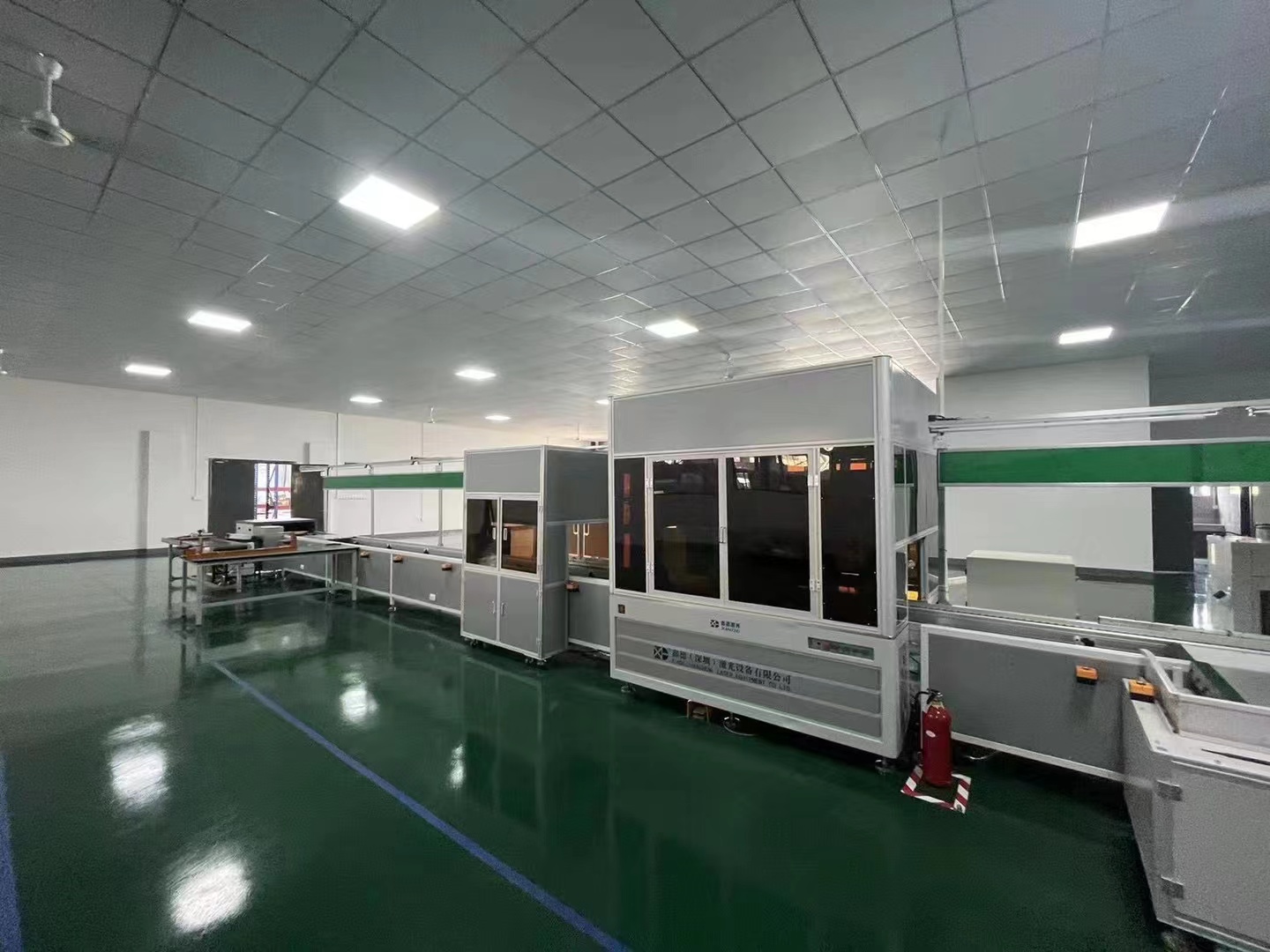

5. laser welding machine is also equipped with work table, work table belongs to non-standard products, need to design according to customer products, the price is not fixed.

Finally, there is branding. Laser welding machine is often tens of thousands, and the technical content is high, the level of after-sales service is high, so we must buy from regular channels, try to choose well-known brands.

First, the well-known brand technology is more mature, the product quality is good, the performance is stable;

Second, the after-sales protection of well-known brands is more perfect.

-

Inquire

- Mobile

- Mobile177-2247-7738

- WeChat

- Tiktok

- Video

- Top